The steel case of a chemical reactor, selective focus. Bp allowable bearing pressure, psi (see Table 3-35) bp bearing stress, psi C compressive load on concrete, lb d diameter of bolt circle, in. Browse 17,565 pressure vessel stock photos and images available, or search for pressure vessel tank or high pressure vessel to find more great stock photos and pictures. Thickness required of skirt at base plate, t^. Notation Ab required area of anchor bolts, in.2 Bj anchor bolt diameter, in. The maximum plate stress using the maximum pressure over a 4.5 strip is then. ' 1.33 Factor B ( tsk E1 = 16 R ~ ' 1.33 S = In the case of anchor bolts embedded in a concrete base, the prescribed tightening procedure has to be followed for safe and reliable operation. Base plates can be square with clustered anchor bolts as shown in Fig.

We can mechanically polish plate surface to mirror finish. = allowable stress, compression, skirt, psi Fb = allowable stress, bending, psi fs = tension force per bolt, lb fc = bearing pressure on foundation, psi Mb = overturning moment at base, ft-lb My = overturning moment at tangent line, ft-lb SEB has the ability to offer different levels of mechanical and electro-polishing finish on the interior and exterior of your pressure vessel. = allowable bearing pressure, concrete, psi Fv = minimum specified yield stress, skirt, psi Fs = allowable stress, anchor bolts, psi fLT = axial load, tension, lb/in.-circumference fix: = axial load, compression, lb/in.-circumference Ft = allowable stress, tension, skirt, psi F.

#Pressure vessel anchor bolt design code#

S - code allowable stress, tension, psi N = number of anchor bolts VVb = weight of vessel at base, lb WT = weight of vessel at tangent line, lb w = width of base plate, in. The turn of the nut method has been used for decades. We can mechanically polish plate surface to mirror finish.E[ = modulus of elasticity at design temperature, psi Ab = cross-sectional area of bolts, in.2ĭ = diameter of bolt circle, in. Pressure Vessel Anchor Bolt Design Bolt pretensioning of pressure vessel anchor bolts are done the same way as anchor bolts for structural columns. Grade B7 Stud Bolts are used in pressure vessels that do not need corrosion resistance, aren’t susceptible to stress corrosion cracking, and for temperatures typically less than 750F. The major function of these anchor bolts is to prevent lateral sliding of the vessel from severe external loadings. For both design methods, the anchor bolt net area used to determine the design values presented in this TEK are taken equal to the following, which account for the reduction in area due to the presence of the anchor threading: in. The bolts are quenched and tempered (a.k.a heat treated) to develop the desired tensile strength (mechanical properties).

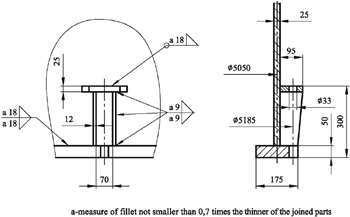

SEB has the ability to offer different levels of mechanical and electro-polishing finish on the interior and exterior of your pressure vessel. The inner and outer sides of a common nuclear boiling water reactor (BWR) pressure vessel support skirt are both anchored by 60 bolts, with the locations and structural configuration shown in Fig. The design of anchor bolts for pressure vessels must conform to the requirements of section. cast-in-place steel anchor bolts designed to resist the stack-induced forces. Our certified craftsmen will meet even the most rigorous requirements, fabricating within your exact specifications. Society of Mechanical Engineers Boiler and Pressure Vessel Code (ASMEB and. SEB designs and fabricates your pressure vessel within the scope of Section VIII, Division 1, of the ASME code.

We also assist in the research and development of custom metal fabricated products for customers with specialized process manufacturing needs and non-standard specifications. Minimum Bolt Spacing is minimum pitch (distance between centres of bolt holes) shall not be less than 2.5 times the nominal bolt diameter is calculated using Minimum Bolt Spacing 2.5 Nominal Bolt Diameter.To calculate Minimum Bolt Spacing, you need Nominal Bolt Diameter (d b). Our pressure vessel and process industry expertise enables us to accommodate custom fabrication requests. Pressure Vessels Fabricator Unfired Pressure Vessels

0 kommentar(er)

0 kommentar(er)